Receiving Part 2

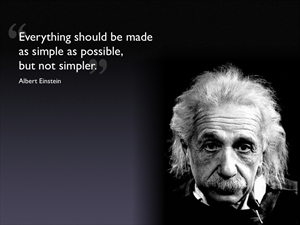

There are two basic questions a receiving manager can ask about each delivery to help with the decision-making process and encourage true dock activity flow:

- How much freight/cargo is scheduled?

- What kind of freight/cargo?

When a carrier calls to make an appointment, if the receiving clerk captures the Purchase Orders and the number of pallets or cases on the delivery, the receiving manager has the key elements to answer these two questions.

Why are these two basic questions important?

The first question, “how much cargo?” helps a manager determine how long it will take to unload the truck. The manager could use that information to decide where to unload (i.e., in what door). The manager can decide what equipment to use. If there is one pallet, a hand pallet jack is sufficient to unload. If the load is 20 pallets, a forklift or a powered pallet truck is the right call. If the load is 600 loose cartons, then the manager could assign two men with a stack of pallets, and plan on two hours of dock time.

The first question, “how much cargo?” helps a manager determine how long it will take to unload the truck. The manager could use that information to decide where to unload (i.e., in what door). The manager can decide what equipment to use. If there is one pallet, a hand pallet jack is sufficient to unload. If the load is 20 pallets, a forklift or a powered pallet truck is the right call. If the load is 600 loose cartons, then the manager could assign two men with a stack of pallets, and plan on two hours of dock time.

The question “how much cargo?” is good data, but shallow by itself. If the schedule also captures the Purchase Order, the receiving manager gains a great deal more information. Looking at the PO, the manager can determine the number of order lines, and the number of SKUs in the delivery. If the delivery is 100 SKUs on two pallets, the manager knows that the unload will be fast but the check-in will take much more time. If the load has 26 pallets but only two SKUs, the manager can assign a single forklift driver to unload and receive the load. In that case, the driver may even execute the put-away.

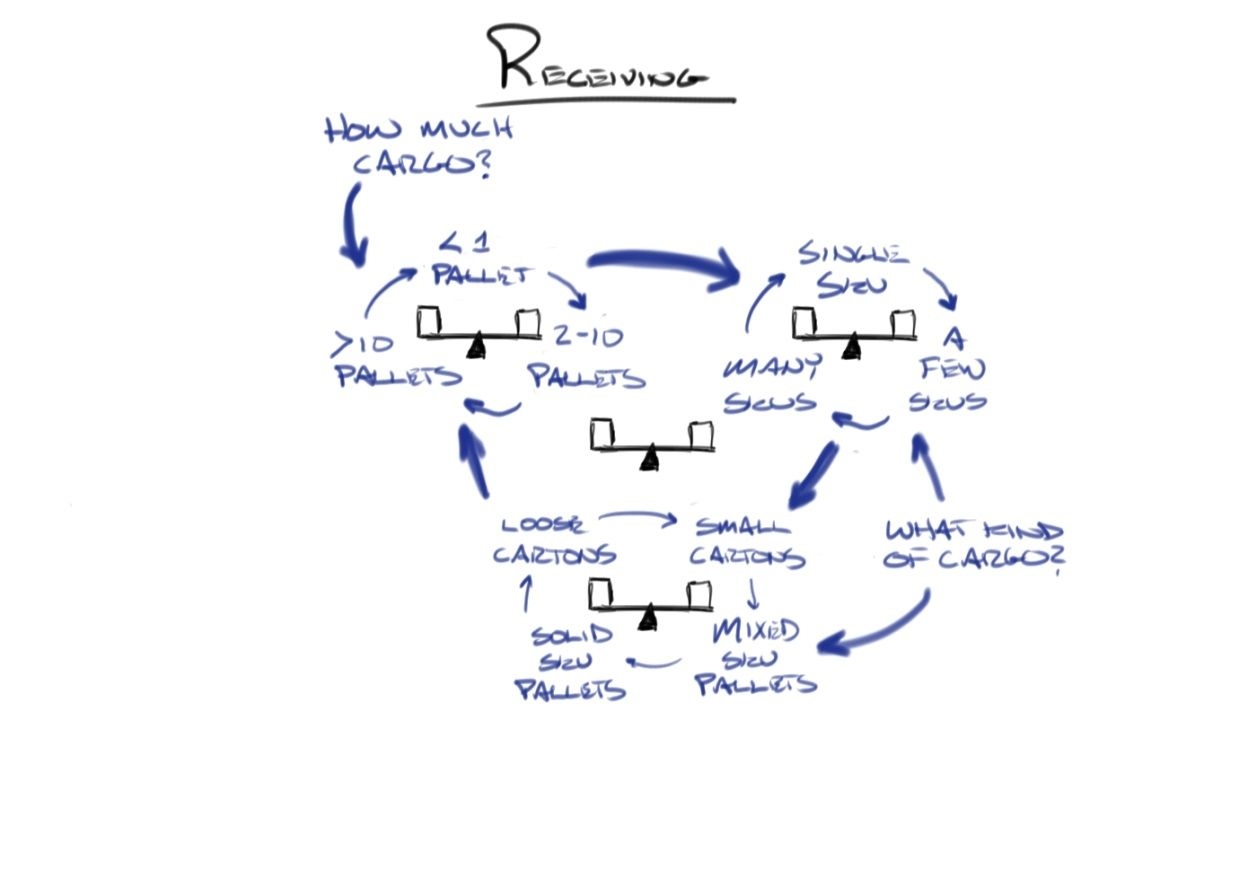

As the drawing above illustrates, these two questions uncover a number of combinations for the load. An experienced receiving manager, knowing these two questions, can make decisions about the door to use, how much space the load requires for check-in, the staff required, and the total elapsed time between truck arrival and when the product is stocked, ready for order selection.

If you think about the possible results of the different combinations, there are 12 different combinations of load. Each combination requires different space, time, equipment and personnel. Knowing the specific combination allows a seasoned manager to make a decision about resource allocation.

Example of Application

As a young manager I had little receiving experience at the distribution center level. Soon after I started my new role, I instituted a Receiving Appointment Program at the DC. The carriers and the vendors complained, as did our buyers. I stuck to my guns and rebuffed requests to stop the program.

One of the first things I started to do was keep a record of the loads in the appointment book. I asked the receiving clerks to pull the Purchase Order paperwork at the end of each day for what was on the schedule. Before I left for the day I reviewed the schedule for the next day, and the POs the clerks pulled.

As I looked at each PO and the schedule, I started to transfer data from the PO to the schedule page. I recorded the vendor name, and the number of SKUs to the schedule. I then scanned order quantity for each SKU on the PO. Looking at the case count, or the pallet count, I made a note about the average quantity per SKU.

After I reviewed each of the planned loads, I assigned the door for unloading, and the people for the load right on the schedule. We kept a whiteboard on the wall outside the receiving office. My late-day routine included posting the next day’s unload schedule on the board.

Tracking Performance

Part of our routine involved capturing the start and end time of a load. When the driver appeared at receiving, the clerks would time-stamp the paperwork with an old time clock. The guys working on the dock recorded the time they finished the unload and the time the driver left. When the load was complete and the paperwork turned in, the clerks time-stamped the paperwork again.

At the end of the day, before I started to look at the next day’s schedule, I looked at the receiving paperwork for that day. Looking at the time stamps, I calculated the time required to unload the truck, and the time to check-in the load and release it for stocking. I posted those times in the appointment schedule, completing a historical record of the effort made that day.

In the first few months, it took a while for me to understand the combinations of the different vendors, the time it took to unload, and the time it took to check-in the freight. As time went by and I gained experience, I did a better job managing the schedule. Dock operations smoothed out and our overtime dropped. Yet, I knew there was still room for improvement.

And that is when I started to think of changing the loop, combining the stocking and receiving processes.