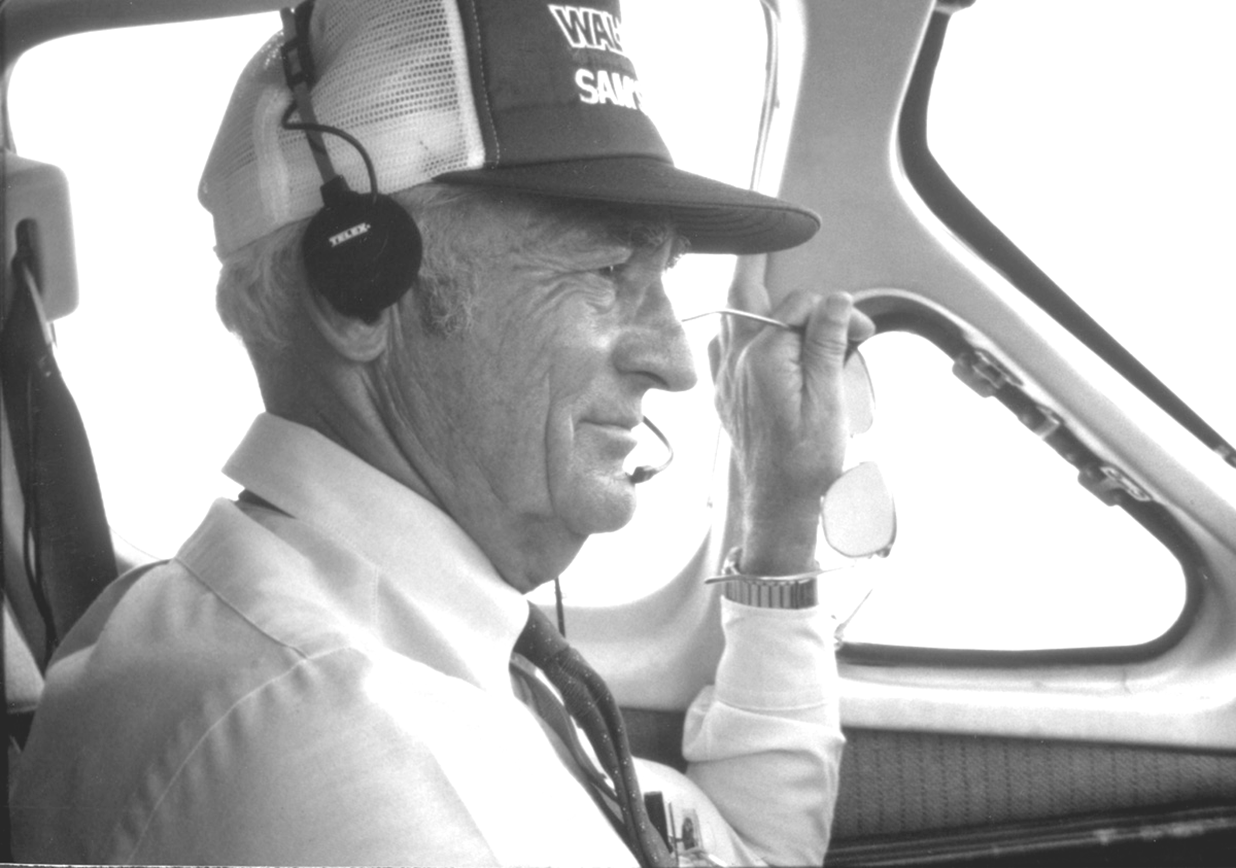

Basic Cost Reduction Strategy: Using Walmart's Inbound Freight Control Initiative to Illustrate Strategy

Sam Walton’s great epiphany when he operated his original Ben Franklin five and dime stores was: as long as the wholesalers controlled the distribution, the wholesalers would control the profit Walton made. Caught between the competitive pricing of the rest of the retail stores who were effectively buying from the same wholesalers, Walton’s stores would always have to fight for customers’ attention. He needed a pre-emption strategy.

Now Sam didn't like the idea of limited profits in a “fair” competition—he wanted to win. When dreaming his new kind of store he developed ways to buy the merchandise direct from the manufacturer and create his own distribution network. That distribution network is the competitive edge that Walmart possesses. Other retailers did the same thing, but Sam Walton set out to make sure that his distribution network was as efficient as it could ever be. He instilled throughout his supply chain the drive to minimize costs at every point, in every link of the supply chain. One of the reasons Walmart has such a strong supply chain organization is that Sam understood in his core that controlling your supply chain is the key to controlling costs.

Now Sam didn't like the idea of limited profits in a “fair” competition—he wanted to win. When dreaming his new kind of store he developed ways to buy the merchandise direct from the manufacturer and create his own distribution network. That distribution network is the competitive edge that Walmart possesses. Other retailers did the same thing, but Sam Walton set out to make sure that his distribution network was as efficient as it could ever be. He instilled throughout his supply chain the drive to minimize costs at every point, in every link of the supply chain. One of the reasons Walmart has such a strong supply chain organization is that Sam understood in his core that controlling your supply chain is the key to controlling costs.

The joke is sometimes made that Walmart is nothing more than a fabulous supply chain that happens to have some retail outlets. It's really not a joke. It is a reality.

Since transportation can be as much as one-half to two-thirds of the total cost of distributing product, it only makes sense to drive as many efficiencies into your transportation network as you possibly can. Walmart's approach—using private fleets to deliver to their stores—is a tactic that helped the company achieve two different strategies. The first strategy was to limit the margin that would have to be paid to a third party providing that service. The second strategy was controlling the fleet, which enables Walmart to control the quality and timing of the movement of freight from the distribution centers to the stores. That second strategy is important. It reduces labor costs and maximizes the utilization of assets and resources. Take it one step further; using that same fleet to backhaul freight from suppliers back into the distribution centers helps offset the cost of running the empty miles from the retail stores back to the distribution centers. Some would call it a “no-brainer,” but so many companies have failed to optimize as well as they could. In fact, I know of companies that waged internal war on the idea. The third strategy was to reduce empty fleet miles, and the tactic by which this is achieved is to pick up the freight from your suppliers.

Walmart followed Drucker's suggestion about using a single tactic to fill multiple strategies. They did this by using the tactic of operating a private fleet to achieve three different strategic goals supporting the main goal—lower prices for the customer.